It's time to Cut it out

Wheather you need one part cut or multiples we can cut it. Profile cutting is our thing and yea – we can easily pocket cut depth shapes as well. Thats easy.

CNC Bit size

We change our bit depending on the job size and material. We make a informed choice about detail required from the job vs the speed of the overall job - this keeps everyone happy!

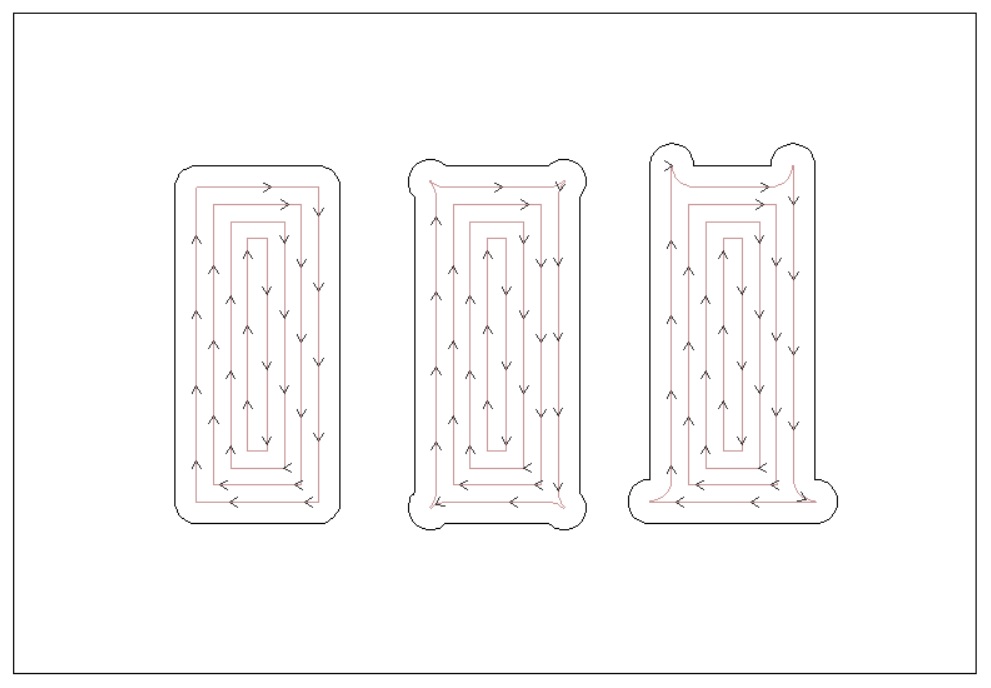

dog bones

We have fancy software that lets us easily create internal corner cuts called dog bones. This is how internal cut accept square edge joinery.

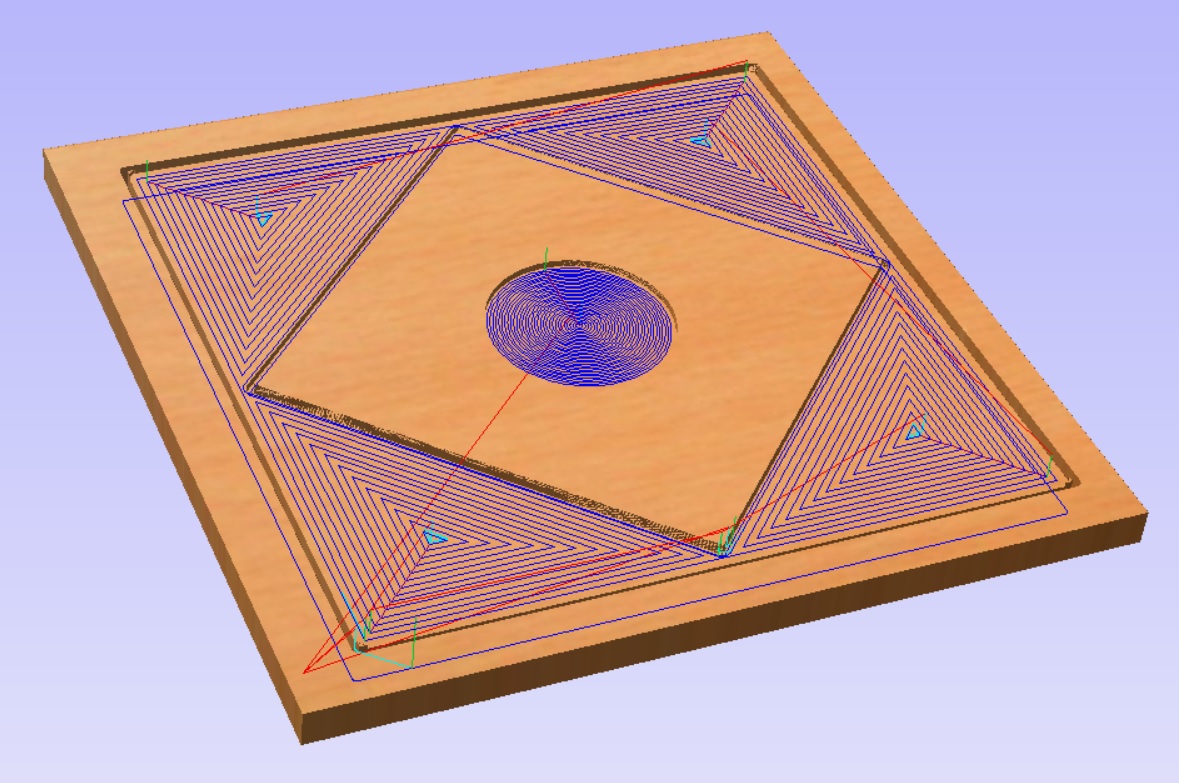

custom toolpaths

Typically we your digital files and nest out profile shapes in our own software. This is our preference as we can control the nesting and spacing requirements of our cnc.

Work Smart Not Hard

(Not to say we don’t work hard – but you get our point!)

Our aim is to get the cleanest result with as little manual effort on our behalf. This is the smartest way to do things in our opinion. Hopefully yours too!

So design our toolpaths so it saves us time and you money.

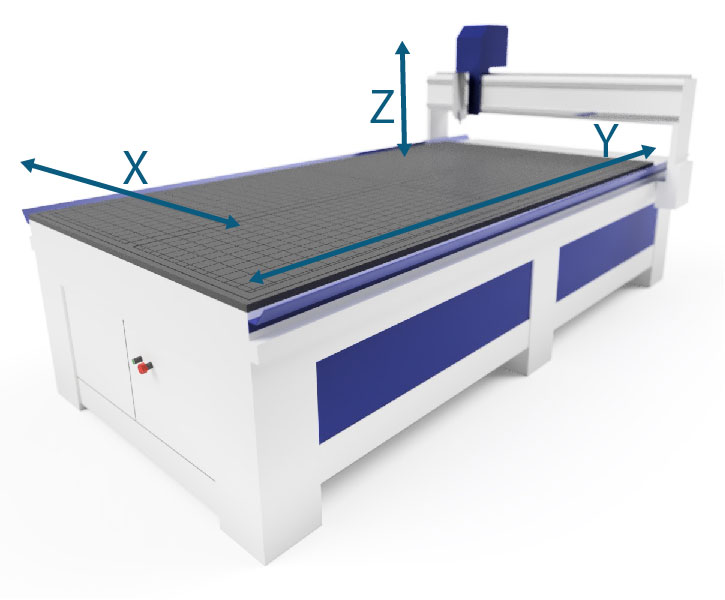

- 150mm

- 2500mm

- 1300mm

Profile cutting Information

what file type do you need?

We work with a range of file types. Our preference is for .DXF or any vector based image.

Or supply a Fusion 360 model – that’ll work too

How many passes?

Depending on the marterial we almost always do one pass cutting. Its faster and we typically get cleaner edge finishing this way.

Do you need bridging tabs?

Yea… we don’t really use bridging tabs. When we think of bridges – it usually means those things you walk across. We generally don’t need them on our projects. We try to be a little more advanced than that!

typical part size and setout?

This has a lot to do with the cnc bit we use on your job. This is why we request you not to pre-nest your supplied files. We can do that for you.

What Our customers say

Carl’s attention to detail, his passion to find the best solution and his design aesthetic all combined to help us create new and exciting products.

Maurice Hillier | Ministry of HandMade

Playdrive's effective collaboration and communication during the design and prototyping phase made problem solving efficient and enjoyable, and led to a smooth production phase

Richard Stride | Designer - WSF Brisbane